| NEWS&TOPICS |

|

|---|

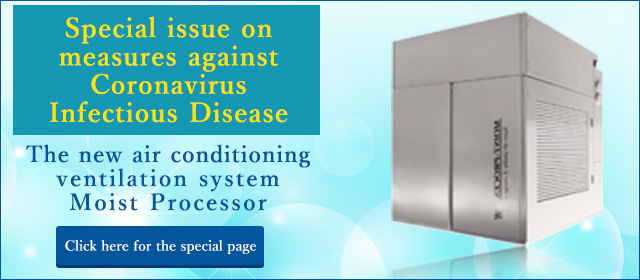

The best solution for humidification and dehumidification

Dyna-Air's Liquid Desiccant Air Conditioning Systems

PRODUCT

INTRODUCTIONAir temperature and humidity are determined by the temperature and concentration of liquid humidity control agents (liquid desiccants) through the use of a mechanism that allows for sufficient contact of the air and the agents.

This simple principle has been applied to the liquid desiccant system, making possible its characteristic powerful humidification/dehumidification.

The liquid desiccant-based humidification/dehumidification method features controllability, humidification/dehumidification capacity, energy conservation and cleanliness that are superior to any other method.

Easy-to-control humidification/ dehumidification and dynamic control of the temperature/humidity of the supply air

The temperature and concentration of liquid desiccants are regulated by control signals, allowing the user to easily adjust the temperature and humidity of the air supply as they desire.

The system delivers the desired temperature/humidity conditions to accommodate various humidity control needs, including gradual changes and constant levels.

Powerful and clean humidification with medium temperature water

The desiccants have a disinfecting effect that prevents bacterial propagation even in a medium temperature range, delivering cleanliness through steam humidification.

Humidification achieved with water at 40℃: from -0.3℃ 35.4% (1.3g/kg') to 27.0℃ 62.6% (14.0g/kg')

Dehumidification performance that achieves a dew point below cold water temperature through low-temperature regeneration (concentration of desiccants).

Specifically, using exhaust heat at about 45℃, low-temperature regeneration with 100% outside air can deliver dew points below cold water temperatures. Dehumidification achieved with water at 10℃: from 34.3℃ 57.0% (19.5g/kg' DP24.6℃) to 20.0℃ 48.2% (7.0g/kg' DP8.7℃)

Support for various heat sources

The system can operate in a temperature range that can maximize the performance of heat pumps. It is possible to use low-grade exhaust heat (around 60℃ or lower temperature), natural heat, or other unused heat sources.

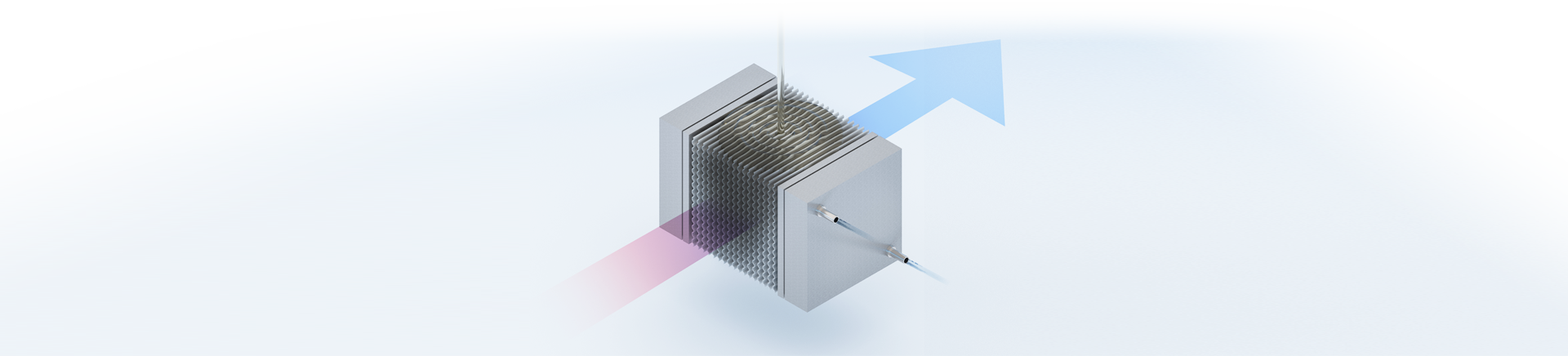

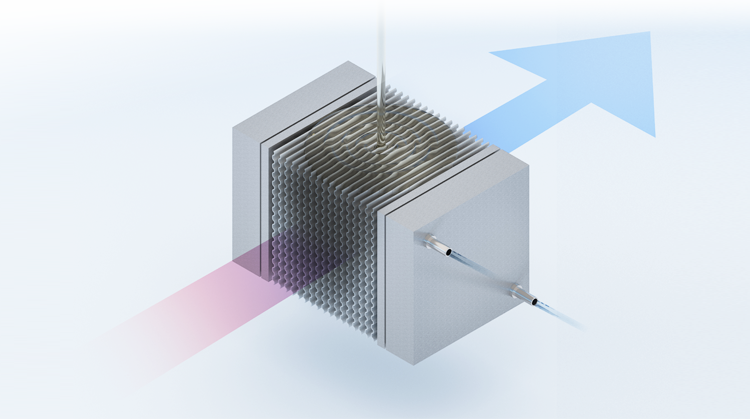

Proprietary heat and moisture exchange mechanism

Dyna-Air has developed a triple fluid heat exchanging mechanism that simultaneously exchanges the heat of air, desiccants, and hot/cold water (high/low-temperature heat) or coolants.

The triple fluid heat exchanger can achieve a high-degree balance between energy efficiency and humidification/dehumidification capacity according to unit size.

SOLUTION

In both the general and industrial-use air conditioning markets, demand for humidity control functions is rising. This reflects the recent trends toward increasing energy saving requirements and health, hygiene and productivity consciousness.

Dyna-Air's Moist Processor resolves various problems that conventional systems have with humidity control processing.

POINT01

Air conditioning that separates latent and sensible heat, which is essential to energy-saving buildings

POINT02

From steam to heat pump, electric type, for industrial,large capacity humidification/ dehumidification systems

POINT03

Powerful humidification / dehumidification for the completely fresh air required in medical facilities

LINE UP

Diverse product lineupThe Moist Processor series offers a broad range of models equipped with different functions, airflow rates and heat sources.

-

Standard model

Provides an airflow rate range between 3000 and 9000 ㎥/h for both humidification and dehumidification. Consists of two independent units: a processor and a regenerator. Installed in many different facilities and factories for outside air processing and humidity management in all seasons. Offers three types of heat sources: built-in, hot/cold water receiving, and hot water receiving.

-

Compact model

Easy-to-install combined unit with an built-in heat source and a processor/regenerator.

Provides both humidification and dehumidification with an airflow rate of up to 1500 ㎥/h. Used for outside air processing in private homes and spot air conditioning in factories -

Humidification specialized model

Large-size, single-unit dedicated heating and humidification machine with a 9000 ㎥/h airflow rate. Used for outside air processing during winter and large-capacity humidification.